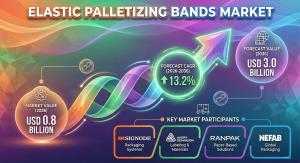

Elastic Palletizing Bands Market to Reach USD 3.0 Bn by 2036, Growing at 13.2% CAGR Amid Reusable Load Securing Systems

Germany’s market grows at 11.8% CAGR as strict packaging laws push firms to replace stretch film with reusable elastic band systems across logistics.

NEWARK, DE, UNITED STATES, February 12, 2026 /EINPresswire.com/ -- The Elastic Palletizing Bands Market is entering a decisive growth cycle, with global demand projected to rise from USD 0.8 billion in 2026 to approximately USD 3.0 billion by 2036, advancing at a CAGR of 13.2%. The Market is evolving rapidly as logistics operators shift away from single-use stretch film toward reusable, polymer-based securing systems that improve load stability and reduce plastic waste.

As supply chains modernize and automation accelerates, elastic palletizing band solutions are becoming core logistics infrastructure, balancing operational efficiency, sustainability goals, and worker safety across global distribution networks.

Discover Growth Opportunities in the Market – Get Your Sample Report Now

https://www.futuremarketinsights.com/reports/sample/rep-gb-31953

Market Valuation & Growth Outlook

• Market size in 2026: USD 0.8 billion

• Market size in 2036: USD 3.0 billion

• CAGR (2026–2036): 13.2%

• Leading load class: Light loads under 300 kg (34%)

• Leading band width class: Narrow (<50 mm) with 38% share

• Key growth regions: North America, Europe, Asia Pacific, Latin America, Middle East & Africa

• Top companies: Signode, Avery Dennison, Ranpak, NEFAB

Market Momentum (YoY Path)

The Elastic Palletizing Bands Market begins its strong upward trajectory at USD 0.8 billion in 2026. By 2028, adoption accelerates as automated palletization formats gain traction across fulfillment centers. Growth momentum continues through 2030, supported by sustainability mandates and warehouse modernization. By 2031, the Market reflects deeper integration of automated banding systems in North America and Europe.

In 2033, circular economy frameworks further strengthen demand across Asia Pacific and Latin America. By 2035, the Market is approaching the USD 3.0 billion milestone, which it achieves in 2036, underscoring a decade of structural transformation in pallet securing systems.

Why the Market is Growing

The Elastic Palletizing Bands Market is expanding due to rising sustainability regulations and operational efficiency requirements. Governments are penalizing single-use packaging under extended producer responsibility frameworks, pushing logistics companies to adopt reusable securing methods.

At the same time, e-commerce growth demands faster palletizing solutions with reduced material use. Elastic bands offer strong tension retention, rapid application, and compatibility with automated systems making them well suited for high-volume distribution networks.

Automation is reinforcing this shift. Robotic banding systems and automated guided vehicles ensure consistent tension application while lowering labor dependency and injury risks.

Elastic Palletizing Bands Market: Segment Spotlight

1) Load Class: Light Loads Lead

Light loads under 300 kilograms account for 34% of the Elastic Palletizing Bands Market. These loads align with modern distribution patterns, including packaged consumer goods and e-commerce shipments. Elastic bands provide fast application and easy removal, improving handling speed while maintaining load stability. Their adaptability across pallet sizes and product shapes makes them a preferred securing method in warehouse environments.

2) Band Width Class: Narrow Bands Dominate

Narrow bands below 50 millimeters represent 38% of total share. Their compact design reduces polymer consumption while maintaining strong elasticity. Narrow bands distribute tension evenly and enhance ergonomics for warehouse workers. Advances in extrusion and polymer blending technologies have improved durability, enabling these bands to support high-volume operational needs efficiently.

3) Polymer Type: Advanced Material Innovation

The Market includes LDPE, HDPE, and PP blends. Manufacturers are focusing on improved elasticity, durability, and stretch performance. Bio-based polymer development is emerging as a sustainability-driven innovation, particularly in North America and Europe, where renewable material adoption is gaining attention.

Drivers, Opportunities, Trends, Challenges

• Drivers: Sustainability regulations are a primary growth driver. Extended producer responsibility frameworks penalize single-use plastic wrapping. Elastic palletizing bands reduce plastic waste significantly while enhancing load integrity. E-commerce expansion also supports demand for efficient and reusable securing systems.

• Opportunities: Automated application integration creates new growth avenues. Robotic banding systems improve palletizing speed and consistency, making elastic bands suitable for high-throughput logistics hubs and automated warehouses.

• Trends: Bio-based polymer adoption is shaping the Market. Manufacturers are developing renewable and biodegradable band formulations that reduce fossil fuel use while maintaining load-securing performance. Automation-led palletization continues to gain momentum across major logistics centers.

• Challenges: Elastic bands are not ideal for all load types. Irregular or unstable pallet shapes may require customized solutions. Upfront investment in automated banding systems can also slow adoption among smaller warehouses. Training requirements remain a barrier in facilities accustomed to manual wrapping processes.

Competitive Landscape

The Elastic Palletizing Bands Market exhibits moderate concentration, with global packaging specialists and regional polymer processors competing on innovation and service differentiation.

Signode maintains a strong position through integrated palletization systems combining elastic bands with automated tensioning equipment and returnable packaging programs. Avery Dennison leverages advanced materials expertise and customized formulations for diverse load weights. Ranpak emphasizes renewable material solutions aligned with European circular economy frameworks. NEFAB integrates reusable containers with elastic banding systems for engineered industrial applications.

Service-driven differentiation including sustainability consulting, application engineering, and closed-loop recovery programs, is increasingly central to competitive strategy.

Scope of the Report

• Quantitative Units (2026): USD 0.8 Billion

• Load Class: Light loads (<300 kg), Medium loads (300–700 kg), Heavy loads (>700 kg), Export pallets

• Band Width Class: Narrow (<50 mm), Medium (50–100 mm), Wide (>100 mm)

• Polymer Type: LDPE, HDPE, PP blends

• Regions Covered: North America, Europe, Asia Pacific, Latin America, Middle East & Africa

• Countries Covered: USA, Canada, Germany, Italy, UK, France, Japan, Australia, and others

• Key Companies Profiled: Signode, Avery Dennison, Ranpak, NEFAB

Why FMI: https://www.futuremarketinsights.com/why-fmi

Have a Look at Related Research Reports on the Packaging Domain:

Export Packaging for Computer Accessories Market - https://www.futuremarketinsights.com/reports/export-packaging-for-computer-accessories-market

Drop-Test-Compliant Packaging for Computer Products Market - https://www.futuremarketinsights.com/reports/drop-test-compliant-packaging-for-computer-products-market

Software Box Packaging Market - https://www.futuremarketinsights.com/reports/software-box-packaging-market

USA Folding Carton Market - https://www.futuremarketinsights.com/reports/usa-folding-carton-market

Physical Media Packaging for Software Products Market - https://www.futuremarketinsights.com/reports/physical-media-packaging-for-software-products-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.